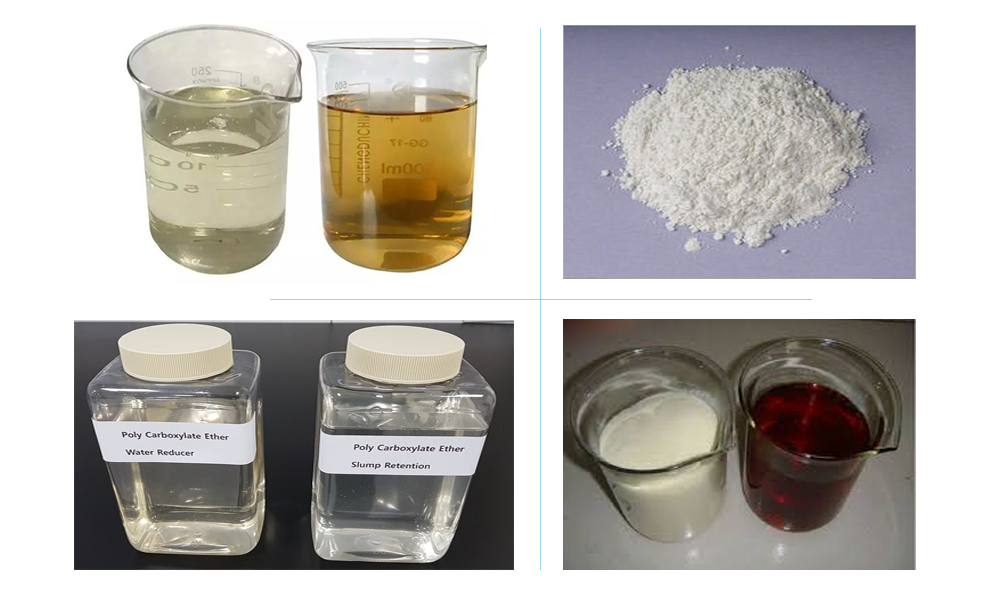

Modern Methods

Modern methods boost efficiency & innovation across industries. AI, automation, IoT, & data analytics drive progress.

Certified

Rust & credibility increase with certifications, assuring customers of quality & reliability..

APPLICATIONS

Experience the Power: Unleash the Full Potential with Our Product's Innovative Applications. Elevate Efficiency, Enhance Performance, and Embrace Transformation. Discover Versatility Redefined - Your Gateway to Success!

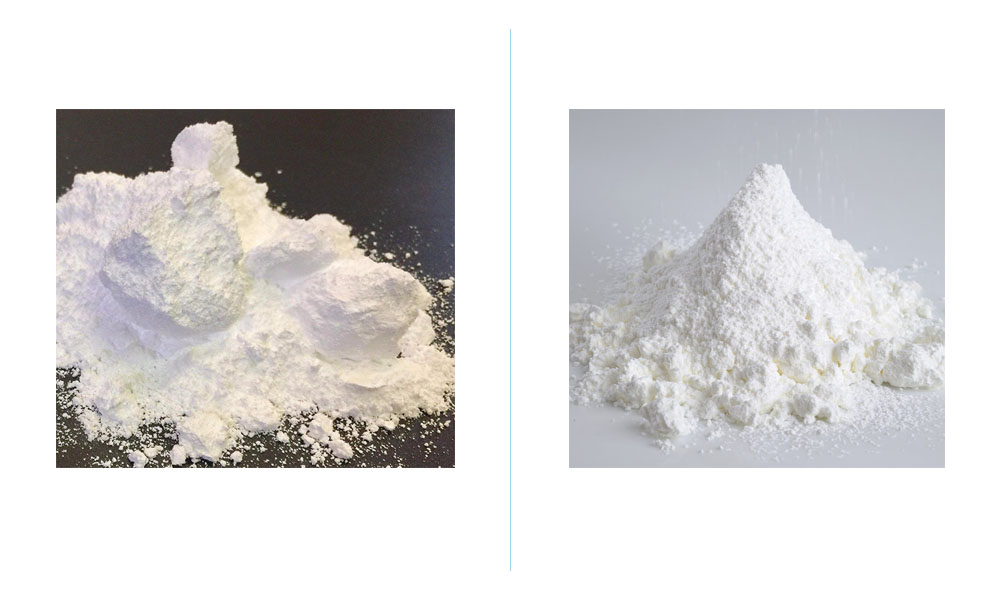

Refractory

Heat-Resistant Powerhouse: Our Refractory Solutions Endure Extreme Temperatures, Safeguarding Industries and Driving Performance

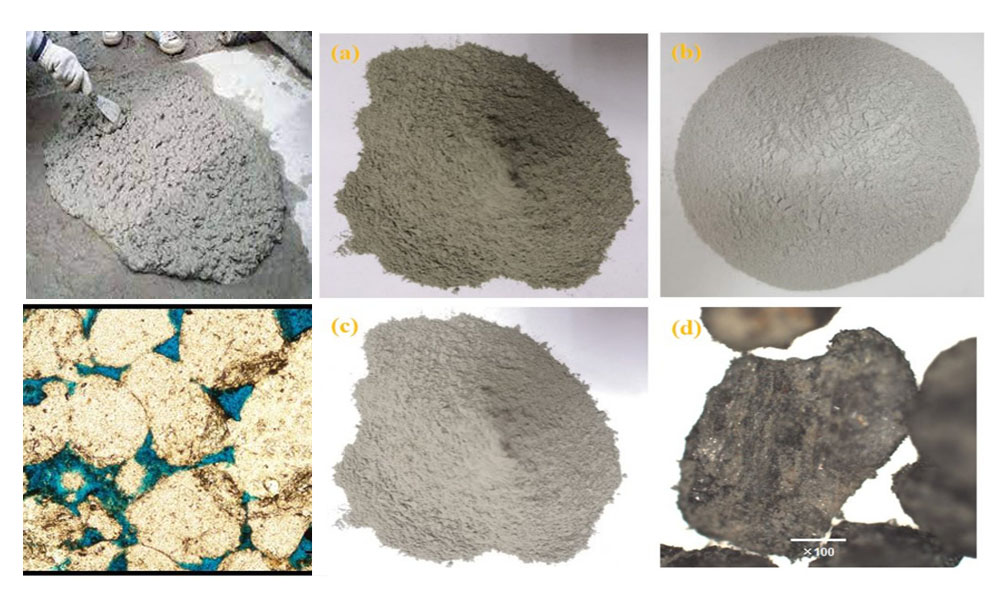

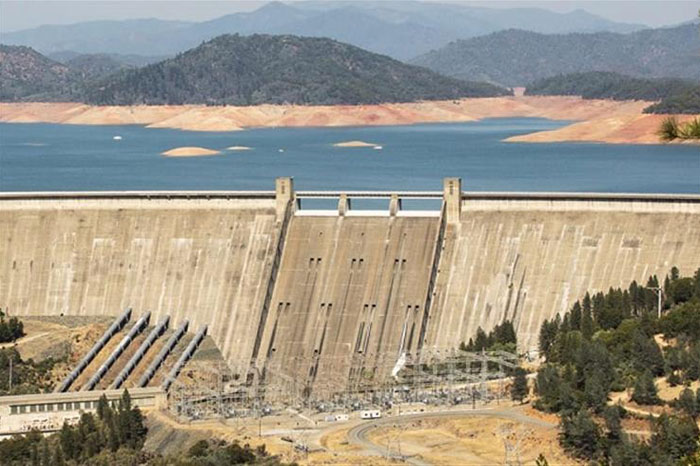

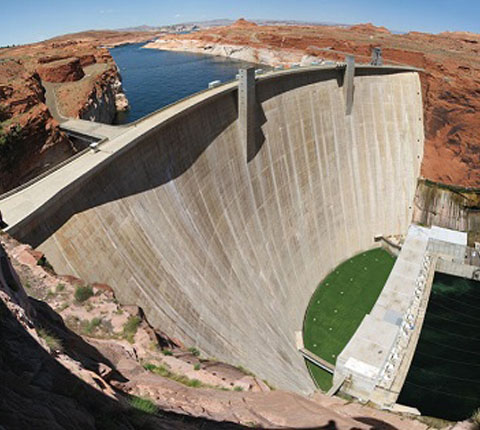

Mass Concreting

Building with Strength: Our Mass Concreting Solutions Deliver Superior Stability and Durability for Large-Scale Construction Projects.

Flooring

Unmatched Flooring Excellence: Elevate Your Space with our Best-in-Quality Flooring Solutions. Beauty, Durability, and Craftsmanship in Every Step.

Basement

Superior Basement Solutions: Experience Unrivaled Quality, Craftsmanship, and Reliability. Transform Your Basement into a Space of Comfort and Luxury.

Tunnels

Engineered for Excellence: Discover Our Best-in-Class Tunnel Solutions. Unmatched Safety, Efficiency, and Innovation, Ensuring Smooth Passage and Lasting Performance.

Damps

Damp Solutions Par Excellence: Count on Us for Top-tier Damp Construction. Superior Moisture Control, Structural Integrity, and Peace of Mind..

Our Services

Unlock Limitless Possibilities with Our Services. Empowering Your Success, One Solution at a Time. Trust in Expertise, Embrace Quality, and Experience Unparalleled Support. Partner with Us for a Journey of Growth and Achievement.

Customization

Our Unique Style, Our Personal Touch. Experience Products/Services Crafted Exclusively for You.

Quality Supervision

Uncompromising Vigilance: Quality Supervision Ensures Impeccable Standards. We Safeguard Excellence, Integrity, and Customer Trust, Every Step of the Way.

Financial Service

Ensuring Excellence: Quality Supervision at its Best. We Guarantee Premium Standards, Precision, and Perfection in Every Aspect.

After-sales Service

Beyond the Purchase: Exceptional After-Sales Service. Our Commitment to Your Satisfaction, Prompt Support, and Enduring Care, Ensuring Your Delight.

ACHIVEMENTS

Pioneering Landmarks: Our Construction Company Boasts a Legacy of Iconic Structures. Awe-Inspiring Projects, Award-Winning Designs, and Client Satisfaction Define Our Achievements.

Latest Blog Post

Lorem Ipsum is simply dummy text of the printing and typesetting industry has been the industry's standard dummy text ever since the been when an unknown printer.

Lorem Ipsum by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal .

Lorem Ipsum by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal .

Lorem Ipsum by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal .

Lorem Ipsum by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal .